Recently, Professor He Daping (School of Physics and Mechanics) and Professor Mai Liqiang (School of Materials Science and Engineering) at Wuhan University of Technology (WUT) achieved a groundbreaking advancement in lithium-ion batteries (LIBs) safety. Their rstudy, titled “Large-scale current collectors for regulating heat transfer and enhancing battery safety,” was published in Nature Chemical Engineering.

WUT is listed as the first-affiliated institution, with Professors He Daping, Mai Liqiang, and Associate Professor Yang Jinlong (Shenzhen University) as corresponding authors, and Dr. Lun Li (postdoctoral researcher, School of Physics and Mechanics) as the first author.

Tackling the Safety Bottleneck in Lithium-Ion Batteries

Despite advances in battery management systems (BMS) and structural designs, intrinsic improvements in thermal regulation remain elusive. One of the primary causes of battery failure is the slow dissipation of internal heat, which lags behind heat generation rates during operation. This leads to:

Localized overheating

Chain reactions of exothermic events

Potential thermal runaway

Traditional metallic current collectors (such as copper and aluminum) have low thermal conductivities (~200–400 W·m⁻¹·K⁻¹), limiting heat dissipation efficiency.

Breakthrough: Large-Scale Graphene-Based Current Collectors

The research team introduced graphene (Gr)-based current collectors, leveraging graphene’s:

Ultra-high thermal conductivity (up to 5300 W·m⁻¹·K⁻¹ at room temperature)

Strong covalent bonding & low atomic mass, enhancing heat transfer efficiency

This approach significantly improves battery safety, offering a new strategy for high-energy-density lithium-ion battery development.

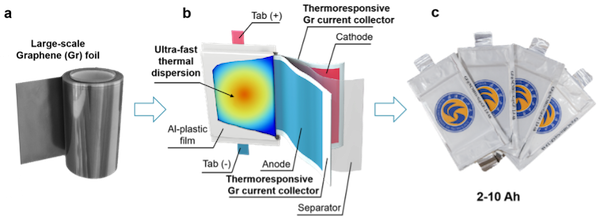

Figure 1. Large-scale fabrication of graphene current collectors and soft-pack lithium-ion batteries.

A Scalable, High-Conductivity Graphene Current Collector

To address critical battery safety challenges, the research team developed a fast temperature-responsive, non-metallic current collector, capable of replacing conventional Cu and Al foils to improve battery thermal regulation.

Using a continuous hot-pressing process, they fabricated meter-scale graphene foils with high alignment and crystallinity, achieving:

Thermal conductivity of 1400.8 W·m⁻¹·K⁻¹

Electrical conductivity of 1.3 × 10⁶ S·m⁻¹

Both values significantly exceed the performance of traditional metal foils.

Key Innovations & Results

1. Scalable Production

Over 100 meters of graphene current collectors successfully fabricated in a single batch

Demonstrates high thermal and electrical conductivity, making it viable for industrial applications

2. Enhanced Battery Safety

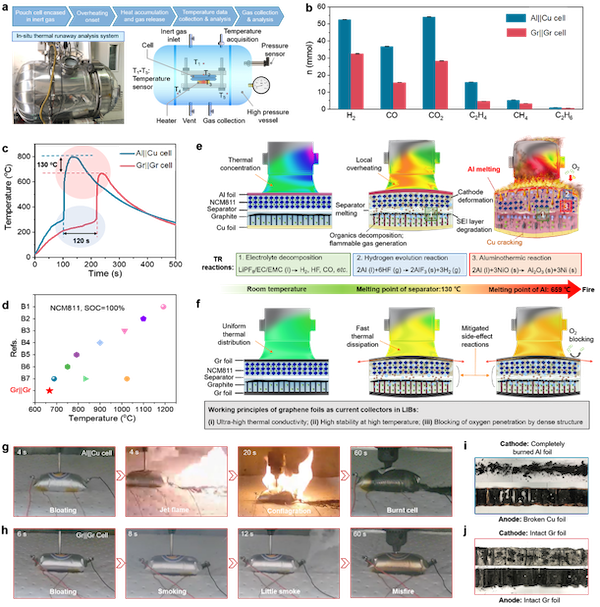

Soft-pack batteries with Gr||Gr electrodes exhibited:

Faster heat dissipation

Lower overall operating temperatures

More uniform thermal distribution during fast charge/discharge cycles

Extreme nail penetration tests confirmed intrinsic safety, with no ignition or explosion

3. Mechanism of Thermal Runaway in Commercial LIBs

For the first time, the study identifies two key chemical reactions behind battery thermal failure:

Aluminothermic reaction: 2Al + 3NiO → Al₂O₃ + 3Ni

Hydrogen-generating reaction: 2Al + 6HF → 3H₂↑ + 2AlF₃

These exothermic reactions intensify combustion and explosion risks during thermal runaway events.

4. Mechanism of Safety Enhancement

Graphene’s superior thermal stability at high temperatures enables rapid heat conduction

Self-regulating temperature mechanisms ensure safe operation under extreme conditions

Figure 2. Safety performance and mechanistic analysis of soft-pack batteries during thermal runaway.

Toward Safer Energy Storage Solutions

This research directly tackles fire and explosion risks in lithium-ion batteries (LIBs), particularly for electric vehicles and large-scale energy storage systems. By replacing conventional Al/Cu foils with next-generation graphene current collectors, the team successfully developed ultra-safe LIBs with fast heat dissipation and high-energy output.

Extensive material characterization using XRD, Raman spectroscopy, SEM, and stress-strain analysis confirmed the structural and functional viability of the graphene foils. Additionally, through industrial-scale process optimization and advancements in welding technology, the team enabled mass production of soft-pack batteries.

Key Performance Achievements

Electrochemical tests demonstrated:

High energy density

Excellent cycle stability in Gr||Gr batteries

Combined with thermal simulation and experimental validation, the study provides new theoretical insights into the design of next-generation safe and high-energy-density LIBs, laying the groundwork for transformative advancements in the energy storage industry.

Article

Information

Lun

Li#, Jinlong Yang#,

Rui Tan#, Wei Shu#, CheeTong John Low, Zixin Zhang, Yu Zhao, Cheng

Li, Yajun Zhang, Xingchuan Li, Huazhang Zhang, Xin Zhao, Zongkui Kou,

Yong Xiao, Francis Verpoort, Hewu Wang, Liqiang Mai,

Daping He*, Large-scale

current collectors for regulating heat transfer and enhancing battery

safety,Nature

Chemical Engineering(2024).DOI:https://doi.org/10.1038/s44286-024-00103-8